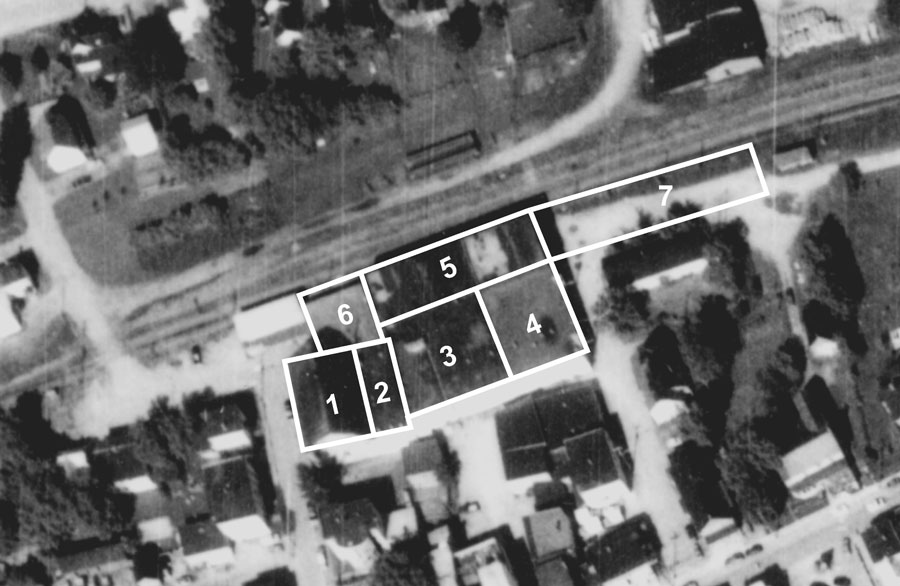

Expansion

Sears and Deckelbaum invest $100,000 to purchase equipment. The number of employees jumps from 10 to 40 and work is divided into three shifts. The business continues to grow and there are several expansions.

Total size of the Filtex plant: Nearly 78,000 sq. ft. (7,230 m2).

| Bâtiments | Description |

|---|---|

| 1. | “the barn”, the original building. |

| 2. and 3. | end of the 1950s + 4,800 sq. ft. (446 m2) and +16,0000 sq. ft. (1,486.5 m2). |

| 4. | 1962: the Corporation de développement industriel de Sutton buys the land on behalf of the Town of Sutton; a 20-year lease/purchase agreement is signed with Yarntex; an 8,500 sq. ft. (790 m2) addition is built. |

| 5. | 1962: land is leased from Canadian Pacific; it adds an additional 15,600 sq. ft. (1,449 m2). |

| 6. | 1983-1984: Yarntex opens on the site of the train station that was demolished in 1969 + 3,420 sq. ft. (318 m2). |

| 7. | 1986: + 18,000 sq. ft. (1,672 m2). |

Since 1955, the textile plant at Sutton had only manufactured thread. To survive, Yarntex had to expand its products line, so in addition to carpet yarn the company started producing such things as embroidery, textured threads, mohair, chenille, knitting yarn and macramé. These products were made of cotton, acrylic, viscose, nylon, orlon and rayon, etc.

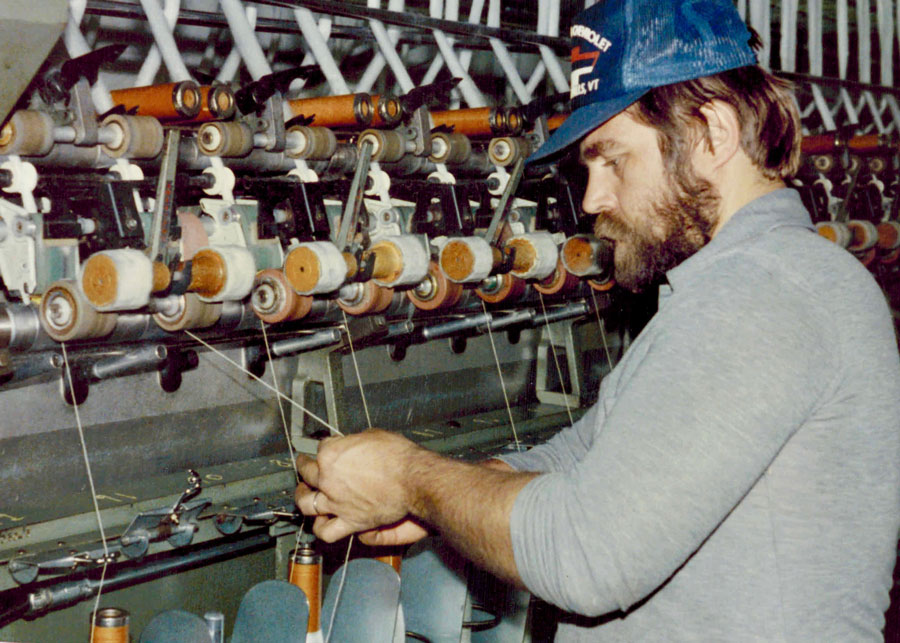

Regardless of the type of thread used, the various production stages are essentially the same. The raw material (natural or synthetic) has to be washed first, then wrung and dried, and then smoothed out (combed and carded) before being spun. The threads are stretched and stretched again to obtain the desired quality and then combined according to the number of strands required. After each operation the threads are wound on spools of various size and shape.

André Daigneault operates a Leesona twister.

To really understand how a spinning mill like the Filtex functioned, one should be familiar with the concept of “twisting” and learn some of the terminology involved.

Charly Talbot, Teddy St-Amour and André Lagimonière explain “twisting”.

Bref, si on veut produire un fil solide, il faut d’abord le « twister ». On peut aussi mélanger les couleurs!

Photo credit: André Daigneault Collection